Data-driven machine learning software to analyze the relationships between additive manufacturing process parameters and material performance.

Senvol ML can be used to analyze data from any AM process, any AM machine, and any AM material. The Senvol ML software helps companies quickly characterize or qualify additive manufacturing materials and processes. Senvol ML assists in developing statistically substantiated material properties in order to reduce conventional material characterization and testing that is needed to develop design allowables.

The Senvol ML software currently contains capabilities that can be used to:

- Rapidly Optimize AM Process Parameters

- Support Qualification of AM Machines & Materials

- Predict Material Properties

- Gain Insights from In-Situ Monitoring Data to Support Quality Assurance

- Minimize Data Generation Costs

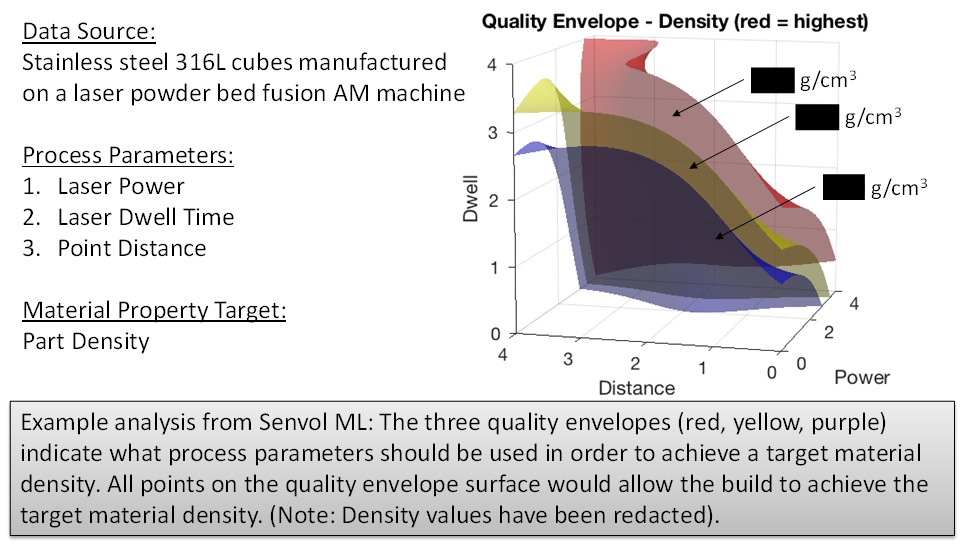

Senvol ML’s capabilities allow users to select the appropriate process parameters on a particular additive manufacturing machine given a target mechanical performance. This presents a unique opportunity to reduce the high level of trial and error that is currently required, which saves a tremendous amount of time and money.

Data-Driven Machine Learning Algorithms

A modularized ICME (integrated computational materials engineering) probabilistic framework for AM data serves as the foundation for the Senvol ML software. In this framework, AM data is categorized into four modules: Process parameters, process signatures, material properties, and mechanical performance. The software is powered by algorithms that quantify the relationships between the four modules. The algorithms are AM material, machine, and process agnostic.

Capabilities of the Senvol ML software include:

- Forward Prediction: Predict mechanical performance (e.g. fatigue life) from a given set of process parameters

- Inversion: When given a target mechanical performance (e.g. a target tensile strength), the software determines what process parameters to use in order to achieve the target

- Machine Learning: The software “learns” from previous data sets and applies those “learnings” to new data sets, thereby reducing the amount of data needed in the future and improving prediction accuracy

- Recommended Data Collection: The software intelligently recommends to the user what additional data points are needed to improve prediction accuracy (i.e. the user is guided to generate smaller, targeted data sets), thereby saving time and money

To read about the U.S. Air Force’s use of Senvol ML, click here.

To read about the U.S. Army’s use of Senvol ML, click here.

To read about the U.S. Navy’s use of Senvol ML, click here.

To read a Metal AM Magazine featured article on Senvol ML, click here.

Access the Senvol ML Software

If your company is interested in gaining access to the software, contact Senvol at info@senvol.com for more details.