The Importance of Additive Manufacturing

Additive manufacturing (AM) – also known as 3D printing – has made tremendous technological progress. Final production parts, such as jet engine fuel nozzles, custom hearing aids, and impellers, can now be printed in materials ranging from polymers to metals. However, just because a part can be produced using AM does not mean that it should be. The key is for a company to understand where and how to adopt AM to achieve increased business profit. As such, a company must view AM as a supply chain solution (not just a manufacturing solution), understand how AM will disrupt their existing business, and most importantly, conduct analyses that quantify the results.

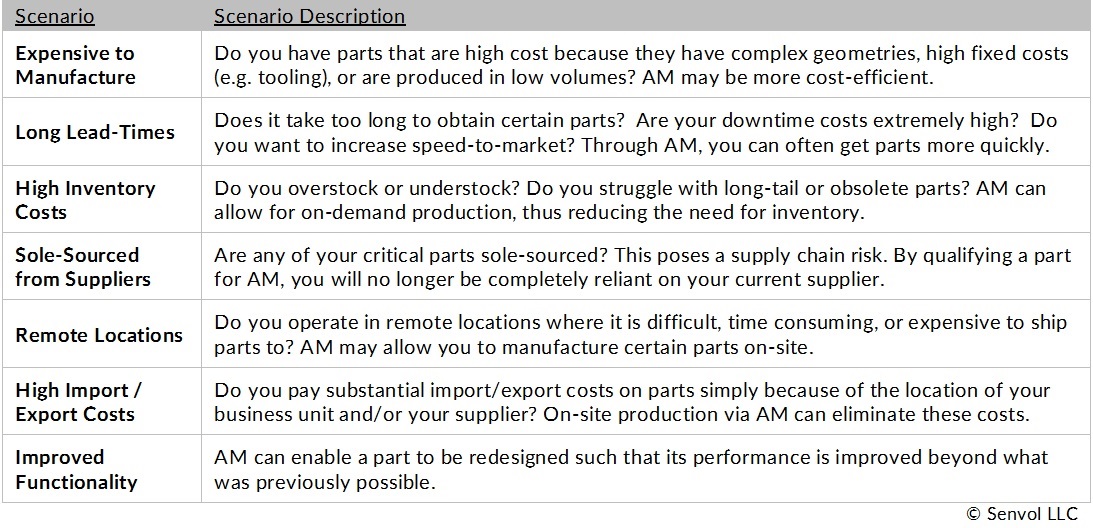

7 Supply Chain Scenarios

Senvol has conducted a variety of quantitative AM analyses for its clients. Based on this work, below are the supply chain scenarios that tend to lend themselves well to additive manufacturing (AM). Parts that fall into one or more of these scenarios may be cost-effective for AM. Parts that do not fall into any of these scenarios will almost certainly not be cost-effective for AM.

To learn about assessing additive manufacturing for your organization, visit Senvol Services.